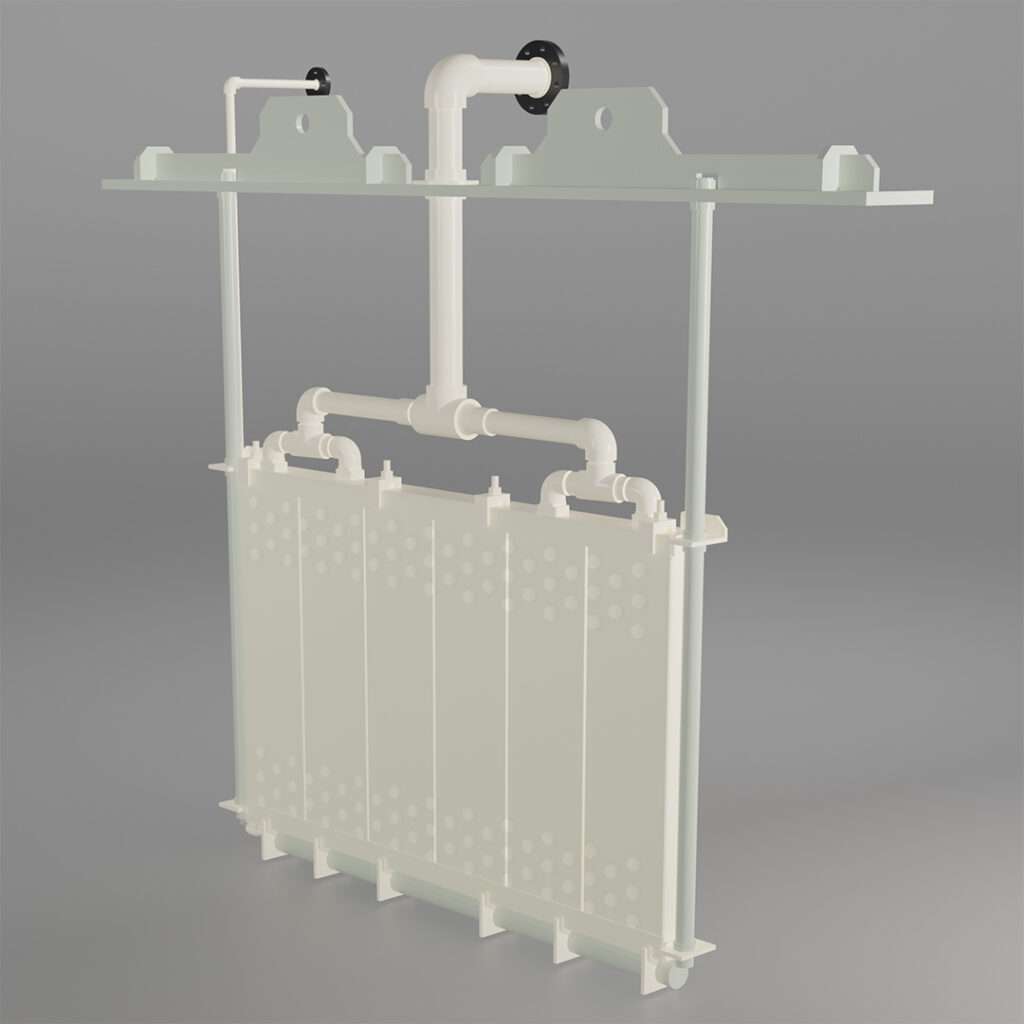

Where high temperatures meet high outputs, steam is a crucial heating medium. With the CALORPLAST concept, steam-operated, corrosion-resistant heat exchangers with the highest surface density can be installed directly in process tanks in a space-saving and cost-effective manner. The distribution of the heating medium steam to a large number of tubes instead of flowing through a capillary distributes any condensate that occurs and thus prevents the effective loss of surface area of conventional heat exchangers in tube or plate design. This ensures process reliability and efficiency at all times.

In cooperation with our experienced engineers, we can customize suspension, piping and connections according to customer requirements for quick installation and easy maintenance.

- Sign up for our Newsletter!

- +49 (0)2151 - 8777-0

- info@calorplast.de

- Mon - Fri: 8:00 - 17:00